Tire Scrap Steel

Tire scrap steel refers to steel obtained from recycling old or used tires. When tires are recycled, they are often shredded or granulated, and various materials are extracted from them, including steel. This steel comes primarily from the tire's reinforcement, which is usually made of steel wires or belts. These steel components are separated from the other materials during the recycling process and can be reused in various applications, such as manufacturing new tires, construction materials, or other steel products. Recycling tire scrap steel helps reduce the demand for virgin steel production and minimizes waste going to landfills, making it an environmentally sustainable practice.

Tire wire scrap or Tire derived steel (TDS) is a light melting scrap produced by the shredding of end-of-life tires

Steelcord, as it is named by tire manufacturers, is a high-quality steel, incorporated into the tire’s structure to withstand bumps, heat, and other hazardous conditions. With its high carbon content, tire wire is considered a high-quality scrap, suitable for melting in an Electric Arc Furnace. Typically 10 to 20% in weight of a passenger car tire is made of Steelcord.

TDS is collected at the end of the granulation process. The current technologies tend to remove the wire at the earliest possible stage, to protect the blades from use and wear further along the processing line. A pre-shredding of car and truck tires, at ambient temperature, is usually followed by a first granulation stage in which, depending on the configuration of the plant, a screener of 15 to 25 mm separates the rubber chips by their sizes.

Directly after the granulation process, a magnetic device separates the steel wire from the rubber. Along with the wires, around 15 to 25% in weight of rubber and textiles is also withdrawn, so the final recovery of the material differs in function of its contamination grade (rubber/fibre).

A key factor in determining the quality of the material is the protection from the atmospheric agents, such as heavy rain and constant moisture. Due to its morphology, the thin wires may easily oxidize, inevitably reducing its quality and the recovery ratio in an electric arc furnace.

Recovery of tire-derived steel

According to the contamination grade, our tire wire scrap can primarily be recycled in metallurgical plants (R4). In case the contaminants (rubber and fibre) are not yet compatible with the technical requirements of some end users, the TDS may be further screened and separated from its impurities by technologies that currently exist in the market. We are happy to assist our partners to get the best performance from all our raw materials.

Physical Properties

A visual inspection shows it is formed by thin and shredded wires, containing different grades of fibre and rubber.

Tab.1 this data is believed to be accurate and was obtained from recognized technical sources, but cannot be warranted as to its accuracy or sufficiency.

Chemical Properties

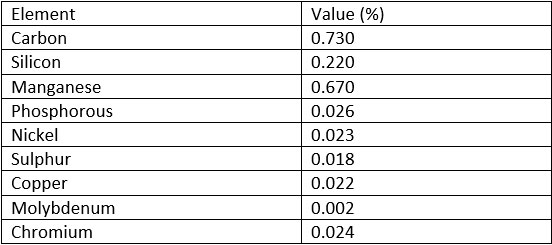

It is a harmonic steel with a high carbon content that can be up to 0.80% and has a bronze/copper coating as highlighted by the chemical analysis below:

Tab.2. Average chemical composition. Please note that these data are believed to be accurate and representative of the average composition, but these details cannot be warranted as sufficient since the chemical composition can vary according to the production plant.

Reviews (5)

Be the first to review “Disney Toys”

I like it!!

Molestiae quam exercitationem quisquam quasi veniam dolores temporibus nam doloribus, cumque quibusdam.

Just outstanding, I recommended!

Ratione quis deleniti error porro ipsum, aspernatur illo nisi officia aliquam similique.

Sounds good, but I hope more.

Nam consequuntur aut, qui eaque molestias excepturi reiciendis quo ut fugit odio.

What a waste of money!!

Quisquam illo iste consequatur qui aspernatur vel mollitia eaque animi autem nemo.

This is extremly recommended!!

Consetetur sadipscing elitr, syosma vero eos et accusam et justo takimata sit amet sed diam nonumy eirmod tempor invidunt.

Submit a review

Your email address will not be published. Required fields are marked *